Chapter 4 Blog: Weaves and Knits

Twill Weaving

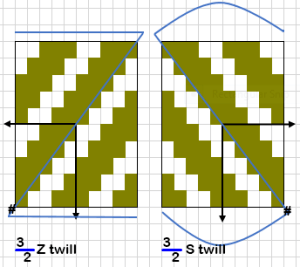

The twill pattern consists of diagonal lines across the fabric but, the direction of the lines means a different pattern. If the diagonal lines go from lower left to the upper right, it is called a right handed twill or a z-twill. When the lines move from lower right to upper left it is considered a left handed twill or an s-twill. There are more distinctions in the twill pattern to help create unique looks to each type. The angle at which the threads are placed changed the look of the twill, normally the angles range between 15-75 degrees. Generally a 45 degree angle is what is considered a traditional twill pattern, these angles depend upon the ratio of warp yarns to fill yarns. Twill angles that are below 45 degrees are considered to be reclining twill and those above are called steep twills. While twills themselves can be defined as a z or s twill, the strands of yarn can also be classified as such. If the angle of the yarn strand matches the slant of the center of the letter "z" then it is a z shaped yarn the same goes for the s shaped yarns. The video I watched on the twill weaving was confusing at times but, I had never known there were so many types of twill weave patterns.

The Fire Test to Differentiate Fabrics

In this article, it address that in order to figure out what type of fabric you have it can be detected by the way it burns or melts. Each fabric has distinctive properties which affects how it reacts to fires. Fabrics that come from natural plants, the cellulose fabrics, all react the same way to a burn. These fabrics include cotton, linen, hemp, rayon, and bamboo. To tell if your fabric belongs in this category, it will burn quickly with white smoke appearing. The smoke will have a similar scent burning leaves. The protein fibers (silk, wool, cashmere etc.) take a longer time to burn and start to curl and crinkle from the flame. Once the flame is gone, the fabric will not stay ablaze which means little smoke is produced. Lastly, the synthetic fibers burn very quickly and do not need the flame to linger for the fabric to still blaze. These fabrics can even start to melt and the smoke produced is black and can become dangerous.

Fabric Testing Tensile Strength Test

During this test the durability and strength of the fabric is tested to see how long the life of the product is. The test strip is measure and placed into clamps so the fabric is vertical. First it is elongated to make sure the extension of the fabric is correct. Once the measurements are correct, the test begins by stretching the fabric slowly until the fabric snaps. The test measures the amount of force used to snap the fabric and also how far the piece of fabric extended until it snapped.

Comments

Post a Comment